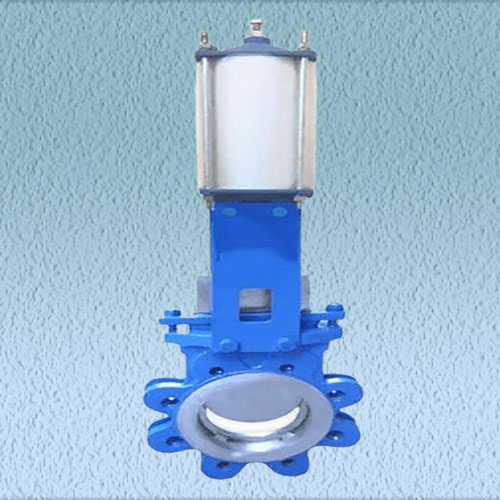

Knife Gate Valves

Knife gate valves are specially designed to handle viscous fluids, slurries, and solids-laden flows.

VSR Global is a prominent manufacturer and service provider of knife gate valves. They offer tailored solutions to meet diverse industrial needs, ensuring reliable performance across various applications.

Knife Gate Valve Types

| Cylinder Details | |

| Barrel | Aluminium Hard Anodized |

|---|---|

| Cover (Top and Bottom) | Cast Steel |

| Piston Rod | BS-970-90, EN-8 Hard Crome Plated |

| Piston | Aluminium Alloy |

| Seals | HI-NITRILE |

| Clamp | ASTM A216 GR. WCB (Investment Casting) |

| Temperature | 850°C maximum |

| Pressure | Up to 6.3 bar |

Standards and Specifications

Knife gate valves are manufactured in compliance with various standards and specifications to ensure safety, compatibility, and performance.

| Standards and Specifications | |

| Item | Single piece body and Uni-directional |

|---|---|

| Operation | Handwheel, Pneumatic, Electric Motorized, Or Control Type |

| Size | 25 mm to 800 mm |

| Valve type | Metal Seated or Soft Seated |

| Body & Gland cover | Cast Iron IS: 210 GR. FG260, ASTM A 216 GR. WCB SS 304, SS 316, SS 316L, SS 317L |

| Gate Material | SS 304, SS 316, SS 316L, SS 317L |

| Seat Material | Integral with body (CI/WCB) or EPDM Integral with body SS 304 or EPDM |

| Gland Packing | Pure PTFE packing material, temperature up to 230°C |

| Standards and Specifications | |

| Bush | Up to DIN 200 Aluminium, Phosphorus, Bronze, and above EN8 |

|---|---|

| Yoke | Mild Steel Epoxy Coated |

| Actuator | Handwheel, Press Steel, Powder Coated, Or C.I Epoxy Coated |

| Working Pressure | 2” to 10” – 10 bar 12” to 16” – 6 bar 18” – 5 bar 20” to 24” – 4 bars |

| End Connection | Lug type or wafer type suitable for BS 10 table ‘E’, PN10, ANSI B16.5 Class 150#, BS 10 table ‘D’ |

| Painting | Except for stainless steel components, all exteriors will be painted with blue epoxy paint. |

Piston Valves

Piston valves are designed for high-performance throttling and isolation in a wide range of industrial applications, providing superior sealing, long life, and minimal maintenance. It is known for their robust construction and excellent shut-off capabilities and is ideal for handling gas, steam, and aggressive fluids at high temperatures and pressures.

With a strong focus on customer satisfaction, VSR Global is your trusted partner for reliable piston valve solutions backed by unmatched service and technical expertise.

Piston Valves Types

Standards and Specifications

Piston valves are engineered for precision, durability, and maximum performance across demanding industrial applications.

| Standards and Specifications | |

| Design | ASME B16.34/API 602 |

|---|---|

| Face to Face | ASME B16.10/ASME B16.11 |

| End to End | SW/BW/Flanged |

| End Flange | ASME B16.5/DIN/BS/IS |

| Screwed End Dimensions | ASTM B1.20.1 |

| BW/SW End | ASME B16.25/ASME B16.11 |

| Testing | API 598 |

Features

Piston valves deliver unmatched performance and safety in various industrial environments. Key features include

| Piston Features | |

| Pressure Ratings | Available in PN 16/40/63 and ANSI Class 150/300 |

|---|---|

| Size Range | DN 15 to DN 200 (½″ to 8″) |

| Material Options | Carbon Steel (CS), Stainless Steel (SS), Alloy Steel, Monel, Hastelloy |

| Superior Sealing | Larger effective sealing area compared to conventional globe valves |

| Plug Designs | Regulating disk, soft seat, and throttling type guided desk |

| Zero Leakage | 100% tight shut-off for reliable performance |

| Safety Certified | Fireproof design for hazardous environments |

| High-Temperature Resistance | Suitable for operations from -10°C to +400°C |

| End Connections | Flanged ends, threaded (screwed) connections, butt weld (BW) & socket weld (SW) ends |

| Actuation Options | Hand lever, gear box, pneumatic, hydraulic, or electric actuators |